|

Guys. It's finally here. The full-sized spinning wheel is live in our Etsy shop. Let me tell you: it was a brutally fulfilling prototyping process. Skeeter, D'artagnan, and Ivan (our 3D printers) printed more than 60 hours of spokes, bobbins, and whorls. Some parts were too small. Some suffered bed shift or other g-code deformities. But, in the end, Irish swears and constant code modifications prevailed. In all of its glory, I present the full-sized, 3D-printed, Irish Tension Good and Basic Spinning Wheel. I'm taking a moment to bask. Go ahead and move on. The wood on this prototype is unfinished. Joseph was too excited to get the thing assembled and didn't take time to finish the wood, which I would probably want to do if I planned to make this my permanent wheel. A good stain would do nicely, I think. I favor the Kona stain from Rust-Oleum, which would provide a lovely, dark contrast to the gold filament. (That's the bronze one in the middle with the dark wood.) To match the red filament, I'm imagining something with a cherry base. Maybe something like Red Oak, again from Rust-Oleum? (All of these stains, incidentally, should be available via your local hardware store or Walmart.)

A little bit more about nuts and bolts. Literally. As he mentions in the listing, this kit does not include a 2-inch 5/16 lag bolt, a 1-inch 5/16 lag bolt, a 3.5-inch 5/16 bolt, a 1.5-inch 5/16 bolt, 2 5/16 lock nuts, misc. washers, and wood screws for the wooden components. You will need to purchase these for yourself. I'm estimating that full assembly time should run somewhere between 30 minutes to an hour, depending on build experience. It might, if you're very methodical like me and check the instructions twice per step, take up to 2 hours. The function itself is beautifully simple. The spinning wheel moves with two rotating pedals. The pedals push a shaft that spins the wheel. The wheel spins the bobbin wheel (see that white or black cord), which then interacts with the flyer. The hooks hold the thread in place while. The piece of black leather is part of the tensioner. And guess what? The whole thing works! (Joseph included a video snippet in the product listing, which I've watched gleefully several times.) He has successfully spun wool thread/yarn from an unprocessed fleece hanging out in my garage. To the bobbin you go, wanton fleece! The kit will--and does--come with loose pieces. The main wheel, for example, is 13 pieces: 6 spokes, 1 hub, and 6 pegs. If you look closely at the picture below, you can see where the spokes connect to the hub, and also where the pegs connect the spoke pieces. Joseph doesn't yet have a build tutorial available. When he does, he'll release it on his Youtube channel, Good and Basic. He'll also release a complete parts list, along with suggestions for cuts. I will say that he built almost the entire wood frame using 1 2x2x8 board, a slab of 2x4 (for the base), and a slab of 1x2 (for the pedals). It took him 30 minutes to put everything together, including cutting the wood. He did know where everything went, which helped, and he also had a saw and a drill. I honestly feel that, with a little bit of reference from the picture above, you'd be able to put together your kit. It's really not that complicated. (If you doubt me, feel free to snort in derision. I still believe in you.) However, like I said, Joseph is working on written instructions and a Youtube tutorial as additional guides. If you have any questions about the spinning wheel or other products, please let us know. Joseph will probably answer most of the questions about product development and design, but if I can answer questions, I will. Let the spinning begin!

0 Comments

Welcome to the Good and Basic Etsy Shop!

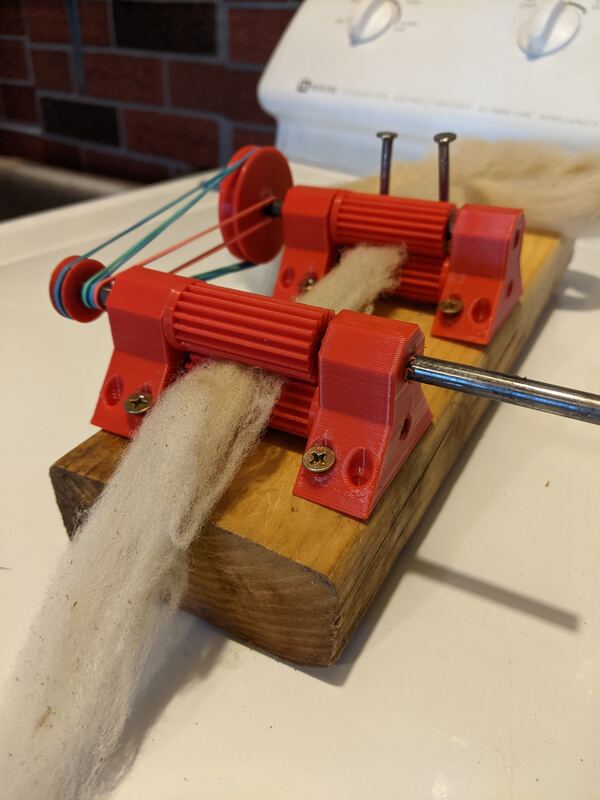

We have recently released the Good and Basic spinning wheel on the shop in two variants: a complete kit that comes with all the 3D-printed parts, all the pre-cut wood parts, and all the nuts, bolts and other fasteners to put it together for $275, and a kit that includes only the 3D-printed parts for $135. I believe this is now the least-expensive castle wheel anywhere on the market. More details on that project in the next post. Designing, prototyping, and reprototyping this wheel to make it high-quality, low-cost, and easy to assemble took the better part of 3 months and a fair bit of inspiration. I am grateful to see the printed parts click together and to see the listings on Etsy in all the color variations. As always, I have released the design files for free on Thingiverse as my contribution to the community. The files and the assembly instructions are free to download and build under a Creative Commons Non-Commercial license. That means that you are welcome to build one for yourself, but I remain the only one who can legally sell them. With the wheel done, I have turned to three other design projects. I have prototyped a flax hackle at the request of a member of our community which could be production-ready in a week or so, and I just finished the first prototype of a 3D-printed ball winder. But the project that is really getting me excited lately is my roving machine or Belni. This machine, when done, will enable you to create your own consistent roving at home! I took inspiration for this project from roving machines that I have seen made in India and more especially from the Ambar Belni, a device that people would use to create the thin cotton slivers that were spun on the Ambar Charkha. This project is aimed at eventually producing a home-scale automatic spinning machine based on the ideas in the Ambar Charkha. It’s hard to overstate how excited I get about that machine. The Ambar Charkha represented a fusion of the best parts of the local production ideals of the Swadeshi movement and the best parts of industry and technology. Rather than using technology to replace people and local skill with centralized factories, the Ambar Charkha, like the washing machine, singer sewing machine, and home computer, enhanced the productive power of the home. This decentralized empowerment of people to take charge of their own things is what gets me excited about 3D printing, learning old-fashioned skills, and sharing what I learn in the process. I hope you will check in to the Good and Basic Etsy shop and Youtube channel often to share the journey with us. If you are excited about our products or videos, please tell a friend about them. We appreciate your help getting the word out. Joseph Bjork Good and Basic. The photos are of the Belni mark 2 and mark 3 respectively. |

RSS Feed

RSS Feed